We manufacture our electrical and diesel engine fire fighting pumps in different types and sizes.

We manufacture fire fighting systems with selection of motors according to related rules. These electrical and diesel engine fire

fighting systems can be used in different facilities with this projects and standards. You can contact our technical team for electrical and diesel fire pump product selection.

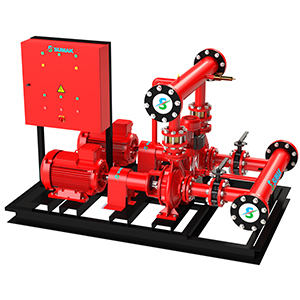

SMT 250/65 EDJY

DESCRIPTION

These are electrical, diesel and jockey fire groups that can pumped water between 12 m³/h and 300 m³/h, conforms with TSE standards.

Manufacturer of fire fighting pumps Turkey.

FIELDS OF USAGE

These types of electrical, diesel and jockey fire extinguishing boosters that can be selected according to power, flow rate and head, are used in military complex , otels , hospitals, business and shopping centers , factories , buildings, warehouses, ships , schools and governancy buildings.

| Pump Body | GG25 Döküm |

| Wheel | GG25 Döküm |

| Shaft | Aısı 420 |

| Liquid Discharge Temperature | 0-45°C |

| Sealing | Yumuşak Salmastra |

| Inlet Flange | DN80 PN16 |

| Output Flange | DN65 PN16 |

| Elektrik / Dizel / Joker Yangın Pompaları | |||||||||

| TİP | DEVİR | ÇALIŞTIRMA | W mm | L mm | H mm | KOLLEKTÖR GİRİŞ | KOLLEKTÖR ÇIKIŞ | mss | m³/h |

| SMT250/32 EDJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1850 | 2350 | 1800 | 4″ | 3″ | 60 80 | 2×28 2×32 |

| SMT250/40 EDJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1850 | 2350 | 1800 | 5″ | 4″ | 60 80 | 2×65 2×50 |

| SMT250/50 EDJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1870 | 2450 | 1835 | 5″ | 4″ | 60 | 2×120 |

| SMT250/65 EDJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1890 | 2550 | 1870 | 6″ | 5″ | 60 80 | 2×175 2×140 |

| SMT250/80 EDJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1900 | 2800 | 2000 | 8″ | 6″ | 60 80 | 2×270 2×240 |

| SMT250/100 EDJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1900 | 2900 | 2050 | 8″ | 8″ | 60 80 | 2×370 2×300 |

SMT 250/65 EEJY

DESCRIPTION

These are two electrical and jockey fire groups that can pumped water between 12 m³/h and 300 m³/h, conforms with TSE standards.

FIELDS OF USAGE

These types of two electrical fire extinguishing boosters that can be selected according to power, flow rate and head, are used in military complex , otels, hospitals, business and shopping centers , factories , buildings , warehouses, ships , schools and governancy buildings.

| Pump Body | GG25 Döküm |

| Wheel | GG25 Döküm |

| Shaft | Aısı 420 |

| Liquid Discharge Temperature | 0-45°C |

| Sealing | Yumuşak Salmastra |

| Inlet Flange | DN80 PN16 |

| Output Flange | DN65 PN16 |

| Elektrik / Elektrik / Joker Yangın Pompaları | |||||||||

| TİP | DEVİR | ÇALIŞTIRMA | W mm | L mm | H mm | KOLLEKTÖR GİRİŞ | KOLLEKTÖR ÇIKIŞ | mss | m³/h |

| SMT250/32 EEJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1200 | 1850 | 1300 | 4″ | 3″ | 60 80 | 2×28 2×32 |

| SMT250/40 EEJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1250 | 1900 | 1500 | 5″ | 4″ | 60 80 | 2×65 2×50 |

| SMT250/50 EEJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1300 | 2150 | 1800 | 5″ | 4″ | 60 | 2×120 |

| SMT250/65 EEJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1500 | 2250 | 1850 | 6″ | 5″ | 60 80 | 2×175 2×140 |

| SMT250/80 EEJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1600 | 2350 | 1900 | 8″ | 6″ | 60 80 | 2×270 2×240 |

| SMT250/100 EEJY SERİ | 3000 | Otomatik ve Manuel Marşlı | 1700 | 2400 | 1950 | 8″ | 8″ | 60 80 | 2×370 2×300 |

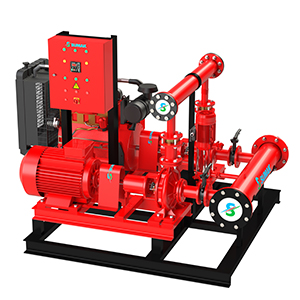

End Suction Fire Fighting Systems

It is an end-suction fire extinguisher created from Volute casing Pumps. Pumps generally consist of a common suction collector and a common discharge collector on a chassis. Since it has a collector, it is not suitable for suction from minus elevation.

End Suction Fire Fighting Systems produced by turkish end suction fire pump producers consist of one main, one spare and jockey pump. In the places where there is no generator, the backup pump is produced from a diesel driven volute pump.

Diesel fire fighting pumps have flow rates between 12 m³/h and 300 m³/h. fire fighting boosters are used in military facilities, hotels, hospitals, business and shopping centers, factories, mass housing, warehouses, ships, schools and social service buildings.

Volute casing Fire Booster manufactured by turkish end suction fire pump producers , are water pumps working with electricity or fuel, produced for use in the fire system by increasing the fire pump water pressures. Fire Pumps, with the help of high pressure, deliver the water they absorb from a certain water reservoir to remote fire cabinets and sprinklers.

Due to the expansion tanks connected to the Fire Boosters, they already hold pressurized water. Fire Booster is a fire fighting system that is formed by integrating one or more pumps from pumps with a minimum 8 bar pressure with flow rates between 12 m³/h – 300 m³/h using a common chassis and collectors.

Fire Pumps produced by turkish end suction fire pump suppliers , These are fire pumps that provide pressurized water in water fighting systems, expressed in nominal flow rate and nominal pressure value. Regarding the selection of end suction fire pumps , They are fire fighting pumps that are used in buildings, industrial facilities, in every area that comes to mind when it comes to service and production, in possible fire situations that can cause great damage to life and property caused by people or the environment.

Taking precautions against every situation that may cause a fire, not after the fire has broken out, is of course a priority. However, due to certain conditions, unconscious personnel, human or material problems, a fire may occur despite all precautions. One of the measures taken in such cases is fire fighting systems.

Let’s summarize the working principles of the Volute Fire pump with a few items;

Diesel fire fighting pumps should be selected to meet the pressure and flow required during a fire; this is one of the critical points in fire pump selection.

End Suction Fire pump systems consist of main and backup pumps. In this sense, it is an important detail to project the main fire pumps as redundant, because in case of possible risks.

Regarding the installation of Fire pumps used in diesel fire fighting systems are controlled by a control panel. A separate control panel for each fire pump These panels are positioned in accordance with the relevant standards and regulations.

Electric motor driven or diesel fire pumps can be used in fire fighting systems.

If the system pressure in the fire fighting installation falls below the value set by the pressure switch of the fire pump, the fire pump is automatically activated.

Signal information comes from the pressure switch and this information is transmitted to the control panel. The Diesel Fire pump is activated according to the incoming pressure information and is deactivated when necessary with the stop switch on the control panel.

Since occupational safety and protection of human health are essential in fire pump systems, the manufacture and combination of products is made in accordance with the standards set by the American Fire Protection Association. This standard is called NFPA 20 for fire pumps and is the most adopted fire fighting standard in the world. Automatic sprinklers, fire cabinets for the building, external hydrant systems are designed according to NFPA 20 Standards. According to this standard, fire pump and pump systems should consist of the following features.

- If the flow at the pump operating point increases by 150%, the operating pressure should not exceed a minimum of 65%.

- Pump closed valve pressure should not exceed 140% of the working pressure.

- The fire pump pressure should be at least 8 bar, the pump should provide the desired water flow at at least 8 bar in order to give healthy pressure to all fire cabinets, sprinklers and fire hydrants in the building.

- The pressure setting of the fire pump is provided through the pressure switch, as in the booster pumps. Users can set how many bars the fire pump can start and stop at via the pressure switch.

- Pump body should be cast iron (GG25-GG40).

- Parts that come into contact with water must be made of water-resistant, non-oxidizing material. Impeller: Bronze (CuSn10), Shaft: AISI 304

- Soft packing should be used as a sealing element in pumps and should be arranged in at least 5 rows.

- “Safety Valve” should be used in fire fighting pump systems to prevent high pressure from damaging system equipment.

- Fire pump fighting systems should be in the form of 1 main + 1 spare + Jockey pump.

- Where there is no generator, the backup pump must be diesel engine driven.

- Bearings should be selected according to 5000 hours life calculation.

- In the facilities where there is enough powerful generator, the backup pump can be electric motor driven.

- Jockey pump operating pressure must be at least 0.7 bar above the fire pump pressure.

- Losses must be calculated with a minimum pressure of 8 bar at the furthest point in the fire system and the pump pressure must be determined.

- NFPA 20 suitable jockey pump selection is 1% of the desired flow rate or 3-3.5 m3/h capacity per hour.