Centrifugal Pumps With Stainless Or Bronze Impeller

These products, which are more resistant to erosion, can be manufactured with bronze impellers or stainless impellers as an alternative to our standard products. Turkey Manufacturer Of Centrifugal Pump.

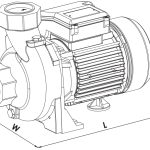

SM100-P

| MOTOR | POMPA | |||||||||||||||||

| TİP | KW | HP | V | Hz | A | d/d | Kapasitör | Çıkış | W | L | H | KG | 2 | 4 | 6 | 8 | 10 | |

| SM100-P | 0.75 | 1 | 220 | 50 | 5.7 | 2900 | 25 | 450 | 1″ | 180 | 303 | 233 | 14 | 29 | 26 | 22 | 16 | 11 |

| SMT100-P | 0.75 | 1 | 380 | 50 | 2.2 | 2900 | – | – | 1″ | 180 | 303 | 233 | 14 | 29 | 26 | 22 | 16 | 11 |

DESCRIPTION

Mono-staged, open impeller centrifugal pumps. This type centrifugal pumps manufactured at frequencies of 50 Hz and 60 Hz.

FIELDS OF USAGE

These type centrifugal pumps are designed for suctioning at a depth of 6 m and it is used in small irrigation up to a maximum of 31 m in height and as a water booster in the buildings not exceeding 8 apartments in 4 floors.

| Pump Body | GG25 Döküm |

| Wheel | Noryl |

| Shaft | Aısı 304 Inox |

| Flow (max) | 11.5 m3 /saat |

| Discharge head | 44 m |

| Liquid Discharge Temperature | 0-45°C |

| Protection Class | IP 54 |

| Insulation | CI.F |

| Mechanical Seal | Seramik/Karbon |

| Pump Withstand Pressure (Pmax) | 6 bar |

*Aşırı yüklemelere karşı SM85 – SM100 modellerde termik koruma mevcuttur.

SM150-P

SM160/2-P

| MOTOR | POMPA | |||||||||||||||||

| TİP | KW | HP | V | Hz | A | d/d | Kapasitör | Çıkış | W | L | H | KG | 2 | 4 | 6 | 8 | 10 | |

| SM150-P | 1.1 | 1.5 | 220 | 50 | 6.3 | 2900 | 25 | 450 | 1½ | 180 | 324 | 246 | 14.5 | 30 | 28 | 25 | 20 | 13 |

| SMT150-P | 1.1 | 1.5 | 380 | 50 | 2.6 | 2900 | – | – | 1½ | 180 | 324 | 246 | 14.5 | 30 | 28 | 25 | 20 | 13 |

| SM160/2-P | 1.1 | 1.5 | 220 | 50 | 6.3 | 2900 | 25 | 450 | 2″ | 180 | 324 | 246 | 14.5 | 26 | 24 | 21 | 15 | 9 |

| SMT160/2-P | 1.1 | 1.5 | 380 | 50 | 2.6 | 2900 | – | – | 2″ | 180 | 324 | 246 | 14.5 | 26 | 24 | 21 | 15 | 9 |

DESCRIPTION

Mono-staged, open impeller centrifugal pumps. This type stainless centrifugal pumps manufactured at frequencies of 50 Hz and 60 Hz.

FIELDS OF USAGE

These type centrifugal pumps are designed for suctioning at a depth of 6 m and it is used in small-scale irrigations up to a maximum of 36 m in height as a water booster in the buildings not exceeding 16 apartments in 4 floors.

| Pump Body | GG25 Döküm |

| Wheel | Noryl (SM300/2 GG25 Döküm) |

| Shaft | Aısı 304 Inox |

| Flow (max) | 34 m3 /saat |

| Discharge head | 32 m |

| Liquid Discharge Temperature | 0-45°C |

| Protection Class | IP 54 |

| Insulation | CI.F |

| Mechanical Seal | Seramik/Karbon |

| Pump Withstand Pressure (Pmax) | 6 bar |

*Aşırı yüklemelere karşı SM150/2-SM160/2 modellerde termik koruma mevcuttur.

SMK220-P - SMKT300-P

| MOTOR | POMPA | |||||||||||||||||

| TİP | KW | HP | V | Hz | A | d/d | Kapasitör | Çıkış | W | L | H | KG | 2 | 4 | 6 | 8 | 10 | |

| SMK220-P | 1.6 | 2.2 | 220 | 50 | 10.3 | 2900 | 45 | 450 | 1¼ | 223 | 424 | 271 | 28 | 49 | 40 | 30 | 19 | – |

| SMKT220-P | 1.6 | 2.2 | 380 | 50 | 4.5 | 2900 | – | – | 1¼ | 223 | 424 | 271 | 28 | 49 | 40 | 30 | 19 | – |

| SMKT300-P | 2.2 | 3 | 380 | 50 | 4.9 | 2900 | – | – | 1¼ | 223 | 424 | 271 | 28 | 55 | 49 | 38 | 25 | 5 |

DESCRIPTION

These type centrifugal pumps are designed for suctioning at a depth of 6 m and it is used in small-scale irrigations up to a maximum of 36 m in height as a water booster in the buildings not exceeding 16 apartments in 4 floors.

FIELDS OF USAGE

These type centrifugal pumps are designed for suctioning at a depth of 6 m and it is used in small-scale irrigations up to a maximum of 36 m in height as a water booster in the buildings not exceeding 16 apartments in 4 floors.

| Pump Body | GG25 Döküm |

| Wheel | Noryl |

| Shaft | Aısı 304 Inox |

| Flow (max) | 10 m3 /saat |

| Discharge head | 60 m |

| Liquid Discharge Temperature | 0-45°C |

| Protection Class | IP 54 |

| Insulation | CI.F |

| Mechanical Seal | Seramik/Karbon |

| Pump Withstand Pressure (Pmax) | 9 bar |

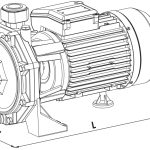

SMKT750-B

| MOTOR | POMPA | |||||||||||||||||

| TİP | KW | HP | V | Hz | A | d/d | Kapasitör | Çıkış | W | L | H | KG | 5 | 10 | 13 | 14 | 15 | |

| SMKT550-B | 4 | 5.5 | 380 | 50 | 11 | 2900 | – | – | 1½ | 229 | 529 | 345 | 51 | 75 | 69 | 60 | 55 | 45 |

| SMKT750-B | 5.5 | 7.5 | 380 | 50 | 14.5 | 2900 | – | – | 1½ | 229 | 529 | 345 | 55 | 82 | 79 | 70 | 63 | 55 |

DESCRIPTION

Double – staged, high altitude pumps. This type stainless centrifugal pumps manufactured at frequencies of 50 Hz and 60 Hz. Turkey Manufacturer Of Centrifugal Pump.

FIELDS OF USAGE

These type centrifugal pumps are designed for suctioning at a depth of 6 m and up to maximum 85 m height pressured water; it is used for irrigation for agricultural purposes, for water booster in buildings up to 32 apartments and 8 floors, for clean water in social facilities, constructions and gas stations. Turkey Manufacturer Of Centrifugal Pump.

| Pump Body | GG25 Döküm |

| Wheel | GG25 Döküm |

| Shaft | Aısı 304 Inox |

| Flow (max) | 16 m3 /saat |

| Discharge head | 85 m |

| Liquid Discharge Temperature | 0-45°C |

| Protection Class | IP 54 |

| Insulation | CI.F |

| Mechanical Seal | Seramik/Karbon |

| Pump Withstand Pressure (Pmax) | 12 bar |

Centrifugal Pumps With Stainless and Bronze Impeller

Centrifugal Pump with Stainless Impeller, these pumps consist of a vane impeller in a body, and the liquid is transmitted to the middle of the impeller from an inlet. The pressure is obtained by rotating the liquid with the impeller.

Regarding the selection of centrifugal pumps with stainless or bronze impellers , The working principle of the Centrifugal pump with bronze fan is as follows. Due to the vacuum created on the suction side of the Chrome Impeller, the liquid enters between the blades of the impeller. The fluid passing between the impeller blades gains a great tangential velocity with the rotational movements of the impeller. Between the Inox Impeller blades and the channels limited by the front and rear profiles of the impeller, the liquid is pushed towards the exit side of the impeller by the effect of centrifugal forces that occur during the rotational movement. The movement created in this way ensures the continuous flow of the liquid and the suction of the pump around the suction.

The kinetic energy contained in the liquid leaving the impeller blades with a great tangential velocity is converted into pressure energy in the volute cavity between the fixed diffuser blades. Centrifugal Water Pumps with Bronze Impeller manufactured by turkish centrifugal pump with bronze impeller producers are machines that increase the energy or pressure of liquids. In this regard, pumps are used to send a liquid from low to high or from low pressure to high pressure. Centrifugal pumps with Stainless Impeller are also used to increase the flow rate and therefore the flow rate of the liquid flowing in a pipe.

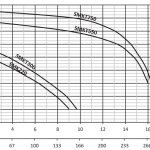

Centrifugal water pump produced by turkish centrifugal pumps manufacturers inlets and outlets are manufactured in types ranging from 1” to 6” inches, with power between 0.50 hp-130 HP, 1450 cycles and 2900 cycles. Stainless Centrifugal Water pump installation is quite simple and easy. Centrifugal pump calculation and selection is very important in terms of choosing the one that suits your needs. The variables of the operating conditions that should be known in the selection of the pump type are mainly as follows: The flow rate (Q) and the desired head (H) values at the operating point.

Regarding the selection of centrifugal pump with bronze impeller , The size and cycle of the pump are determined from the pump selection curves. Other parameters such as efficiency, pump motor power and HPSH values of the selected pump are also read from the pump performance curves.

When choosing Inox Fan Centrifugal Pumps, it should be selected in accordance with the required flow rate and pipe resistance.

When using speed-controlled pumps, always choose a pump whose duty point is as close to the best efficiency point as possible. There are often several alternatives and an important rule of thumb is to choose a pump that is within ±10% of the best efficiency point. When using a speed-controlled pump, the duty point should always be within 10% of the best efficiency point. This will ensure that there is a sufficiently large flow area to be able to adjust while regulating the pump. As for chrome centrifugal water pumps, these pumps consist of a vane impeller in a body, and the liquid enters the pump through a suction pipe.

Installation of centrifugal pumps , The path of the liquid in a centrifugal water dynamo is as follows. Due to the vacuum created on the suction side of the impeller, the liquid enters between the blades of the impeller. The fluid passing between the impeller blades gains a great tangential velocity with the rotational movements of the impeller. Between the impeller blades and the channels bounded by the front and rear profiles of the impeller, the liquid is pushed towards the exit side of the impeller by the centrifugal force that occurs during the rotational movement.

, The movement created in this way ensures the continuous flow of liquid and suction from the suction side of the pump. The kinetic energy contained in the liquid leaving the impeller blades with a great tangential velocity is converted into a pressure force in the volute cavity between the fixed diffuser blades.

The highest pressure is achieved with a given rotational speed. This kind of pump can be said to be a hydrodynamic pump.