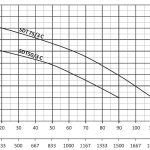

1450 rpm Body-Cooled Drainage Submersible Pumps

This type of pumps due to have 5.5HP and 7.5HP, 1450RPM and 3” outlet, is extremely suitable in order to discharging of fluids up to max 18 meter and 1.5-2.5 kg/cm3 density. The system with stainless agitator which mounted the pump shaft reduces the fluid density; provides economic solutions in the discharging in constructions, backwaters, heavy septics, tunnel works, barrage works, mines and sand areas. Sumak Pump is one of the leaders of submersible pumps and mud water submersible pumps manufacturers in Tukey. The models of slurry water submersible pumps and mud pumps manufacturing in Turkey are SDT50/3C and SDT75/3C

The Control panel which is given with 10meter cable and float switch, can stop the pumps sticks or blokages, burning of motors with the activations of thermic, phase failures, working without water. Also electric motors with the (L1-L2-L3) Energy signs on control panel has high efficiency and thermistor protection. Turkey manufacturer of drainage water pump.

SDT75/3 C

| MOTOR | POMPA | |||||||||||||||

| TİP | KW | HP | V | Hz | A | d/d | Çıkış | Q | H | KG | ∇ | 20 | 40 | 60 | 80 | 100 |

SDT50/3 C | 4 | 5.5 | 380 | 50 | 9.5 | 1450 | 3″ | 360 | 880 | 130.5 | 7 | 12 | 10.5 | 7 | – | – |

SDT75/3 C | 5.5 | 7.5 | 380 | 50 | 12 | 1450 | 3″ | 360 | 880 | 137.5 | 7 | 16 | 15 | 13 | 10 | 5 |

DESCRIPTION

Casting body, three-phase, body-cooled drainage submersible pumps. It is manufactured at frequencies of 50 Hz and 60 Hz. Because of body cooling, it can work for a long time. Turkey manufacturer of drainage water pump.

FIELDS OF USAGE

This type pumps using at, drainage of puddles, rain and floodwaters in channels and pits up to a maximum height of 35 m, excavation pits with high flow, floors of residential units and industrial facilities. Turkey manufacturer of drainage water pump.

| Pompa Gövdesi | GG 25 Döküm |

| Çark | Paslanmaz Çelik |

| Karıştırıcı | Paslanmaz Çelik |

| Mil | Aısı 420 |

| Debi (max) | 120 m3 /saat |

| Basma Yüksekliği | 17.5 m |

| Sıvı Basma Sıcaklığı | 0-30°C |

| Koruma Sınıfı | IP 68 |

| İzalasyon | CI.F |

| Kablo Uzunluğu | 10 m |

| Mekanik Salmastra | Silusyum/Silusyum |

| Pompa Dayanma Basıncı (Pmax) | 8 bar |

Body Cooled Drenaige Submersible Pumps

The design of Sumak SDT / Z series Body Cooled Drainage Submersible Pumps is different than other submersible pumps. Its body is specially designed to cool itself without being completely submerged in water. The pump pumps the water around the motor to the outlet, thus cooling the pump motor. Cast Body Vortex Impeller Drainage Submersible Pumps With Body Cooled produced by Turkish drainage submersible pump manufacturers are suitable for use in mines, tunnel construction, evacuation of turbid water in canals and pits, discharge of rain flood water in excavation pits with high flow, mine water discharge, in industrial facilities. Body Cooled Drainage Submersible Pumps are designed and manufactured in accordance with TS 12599 standard. In the electric motor windings, F insulation class cables are used in accordance with TS 60085:2011. User and motor safety are prioritized by using a 2-pole asynchronous motor with IP 68 protection class in accordance with TS 3033 EN 60529.

It has the possibility of use in different areas with its special impeller designs and the ability to press different waste water liquids depending on the impeller structures. SDTV / Z and SDTV / ZY series submersible pumps, produced with modern casting and manufacturing technology, can be manufactured from different materials according to application areas and customer demands. Necessary precautions have been taken to prevent liquid leakage in the pump motor body components and where the motor supply cable enters the body.

In order to provide sufficient cooling of the self-cooled Submersible Pump motor manufactured by Turkish self cooled submersible producers , it must be ensured that sufficient fluid flow is provided around the motor. Submersible pumps to be used in large volume environments such as caisson wells, water tanks or pools must be used with a cooling jacket.

Every possible information about the Self-cooled submersible pump produced by turkish self cooled pump manufacturers in the well should try to be used for monitoring and control purposes. User personnel should be informed about how to use devices such as the manometer at the well outlet that can be used to obtain information about the pump, electric motor and the status of the system, the electric control panel of especially high power submersible motors, the voltmeter and ammeter, which are used to monitor the current and voltage of each phase on it.

Electrical control panels must be at a level that can protect the submersible motor in case of problems such as high or low voltage, voltage imbalance between phases, which may arise from the electrical network. In addition, it is extremely important that the settings of the system used to protect the electric motor from excessive current are of a type that will not be affected by the ambient temperature. The setting of the overcurrent protection system in the electrical control panel should never be set to a value higher than the nominal current value specified on the motor nameplate in single-phase or direct-start systems.

For safety reasons, it is recommended to set it to 90% of the rated current on the nameplate. In star-delta starting systems, the motor thermal protection should not be set higher than 57% of the rated current specified on the nameplate. The label should be set as a safe value to answer the question of what is the pump. It is recommended to set it to half the tag current as a safe value.

In order to prevent the self-cooled Submersible Pump produced by Turkish self cooled submersible pump manufacturers from being damaged by dehydration, it must be checked that the dry running protection system is operational during the commissioning process, and the sensitivity of the level electrode must be adjusted from within the electrical control panel.

Selection of turkish self cooled submersible pump is important Limiting the number of switchgears of a submersible motor with body cooling is a must. In systems where protection against dry running is provided by one or two electrodes, the engine should not be started immediately after the water level has returned to normal, but should be started after a minimum delay of 5 minutes. In hydrophore applications using body-cooled Submersible pumps, performing the lower and upper pressure settings of the pressure switch to keep the number of switchgears at the desired level and checking that the closed expansion tank is at the appropriate volume will prevent possible damage.