We manufacture our split case, double suction, electrical and diesel engine fire fighting systems in different types and sizes.

Our split-case, double suction pumps can be produced with Electrical and Diesel Engine options in projects with values of 60 m³/h – 300 m³/h.

You can contact our technical team for the selection of our Split-Case Double Suction fire fighting systems.

SMC 310/100 DY

DESCRIPTION

These are, diesel fire groups that can pumped water between 60 m³/h and 300 m³/h, conforms with standards

FIELDS OF USAGE

These types of diesel fire extinguishing boosters that can be selected according to power, flow rate and head, are used in military complex , otels , hospitals, business and shopping centers , factories , buildings , warehouses, ships , schools and governancy buildings

| Pump Body | GG25 Döküm |

| Wheel | GG25 Döküm |

| Shaft | Aısı 420 |

| Liquid Discharge Temperature | 0-45°C |

| Sealing | Yumuşak Salmastra |

| Inlet Flange | DN150 PN16(SMC 310/100) |

| Output Flange | DN125 PN16(SMC 310/100) |

| Inlet Flange | DN125 PN16(SMC 270/80) |

| Output Flange | DN80 PN16(SMC 270/80) |

SMC 310/100 EY

DESCRIPTION

These are electrical fire groups that can pumped water between 60 m³/h and 300 m³/h, conforms with standards.

FIELDS OF USAGE

These types of electrical fire extinguishing boosters that can be selected according to power, flow rate and head, are used in military complex , otels, hospitals, business and shopping centers , factories , buildings , warehouses, ships , schools and governancy buildings.

| Pump Body | GG25 Döküm |

| Wheel | GG25 Döküm |

| Shaft | Aısı 420 |

| Liquid Discharge Temperature | 0-45°C |

| Sealing | Yumuşak Salmastra |

| Inlet Flange | DN150 PN16(SMC 310/100) |

| Output Flange | DN125 PN16(SMC 310/100) |

| Inlet Flange | DN125 PN16(SMC 270/80) |

| Output Flange | DN80 PN16(SMC 270/80) |

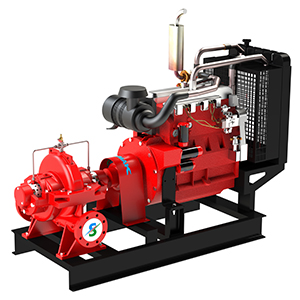

Split Case Double Suction Fire Extinguishing Systems

Double Suction Fire Booster manufactured by turkish double suction fire pump producers , are water pumps working with electricity or fuel, produced for use in the fire system by increasing the fire pump water pressures. Fire Pumps, with the help of high pressure, deliver the water they absorb from a certain water reservoir to remote fire cabinets and sprinklers.

Double suction split case pumps, produced by turkish double suction split case pump manufacturers , also known as Split Case, are centrifugal pumps with impeller model that sucks from both sides. The suction and discharge ports of the pump are in opposite directions. Balancing is provided by bearings placed on the shaft in a symmetrical position. Maintenance is easy as the upper part of the body can be easily dismantled.

Due to their symmetrical structure, they work in a very balanced way. The double suction impellers used give better NPSH performance, while the axial forces are kept at a very low level. They can reach higher flow rates than end-suction pumps and have a lower risk of cavitation.

It can be used in systems where high flow rate is required. Split casing centrifugal pumps produced by turkish double suction split case fire pump suppliers , are primarily preferred to fire suppression systems. Split casing centrifugal pumps are primarily preferred to fire suppression systems.

Regarding the selection of double suction pumps , Our detachable body , Double Suction pumps can be produced with Electric and Diesel Engine options in application projects with values of 60 m³/h – 300 m³/h.

If the system pressure in the Double Suction fire extinguishing installation falls below the value set by the pressure switch of the fire pump, the fire pump is activated automatically. Signal information comes from the pressure switch and this information is transmitted to the control panel.

The fire pump produced by turkish split case fire system manufacturers, is activated according to the incoming pressure information and is deactivated when necessary with the stop switch on the control panel. According to the fire pump installation scheme, it must be returned to the water tank by using a safety valve to prevent excessive pressure in the installation.

Since work safety and protection of human health are essential in Double Suction Fire pump systems, the manufacture and combination of products is made in accordance with the standards set by the American Fire Protection Association. This standard is called NFPA 20 for fire pumps and is the most adopted fire extinguishing standard in the world.

Automatic sprinklers, fire cabinets for the building, external hydrant systems are designed according to NFPA 20 Standards. According to this standard, fire pump produced by turkish split case fire pump manufacturers, and pump systems should consist of the following features.

Regarding the selection of double suction split case fire pumps ,

- If the flow at the pump operating point increases by 150%, the operating pressure should not exceed a minimum of 65%.

- Pump closed valve pressure should not exceed 140% of the working pressure.

- The fire pump pressure should be at least 8 bar, the pump should provide the desired water flow at at least 8 bar in order to give healthy pressure to all fire cabinets, sprinklers and fire hydrants in the building.

- The pressure setting of the fire pump is provided through the pressure switch, as in the booster pumps. Users can set how many bars the fire pump can start and stop at via the pressure switch.

- Pump body should be cast iron (GG25-GG40).

- Parts that come into contact with water must be made of water-resistant, non-oxidizing material. Impeller: Bronze (CuSn10), Shaft: AISI 304

- Soft packing should be used as a sealing element in pumps and should be arranged in at least 5 rows.

- “Safety Valve” should be used in fire extinguishing pump systems to prevent high pressure from damaging system equipment.

- Fire pump extinguishing systems should be in the form of 1 main + 1 spare + Jockey pump.

- Where there is no generator, the backup pump must be diesel engine driven.

- Bearings should be selected according to 5000 hours life calculation.

- In the facilities where there is enough powerful generator, the backup pump can be electric motor driven.

- Jockey pump operating pressure must be at least 0.7 bar above the fire pump pressure.

- Losses must be calculated with a minimum pressure of 8 bar at the furthest point in the fire system and the pump pressure must be determined.

- NFPA 20 suitable jockey pump selection is 1% of the desired flow rate or 3-3.5 m3/h capacity per hour.